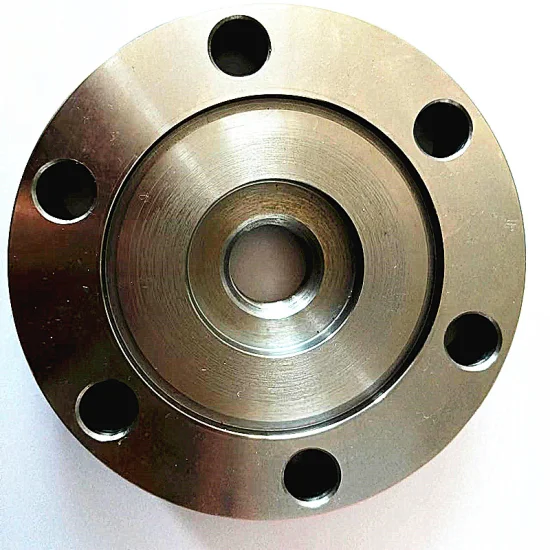

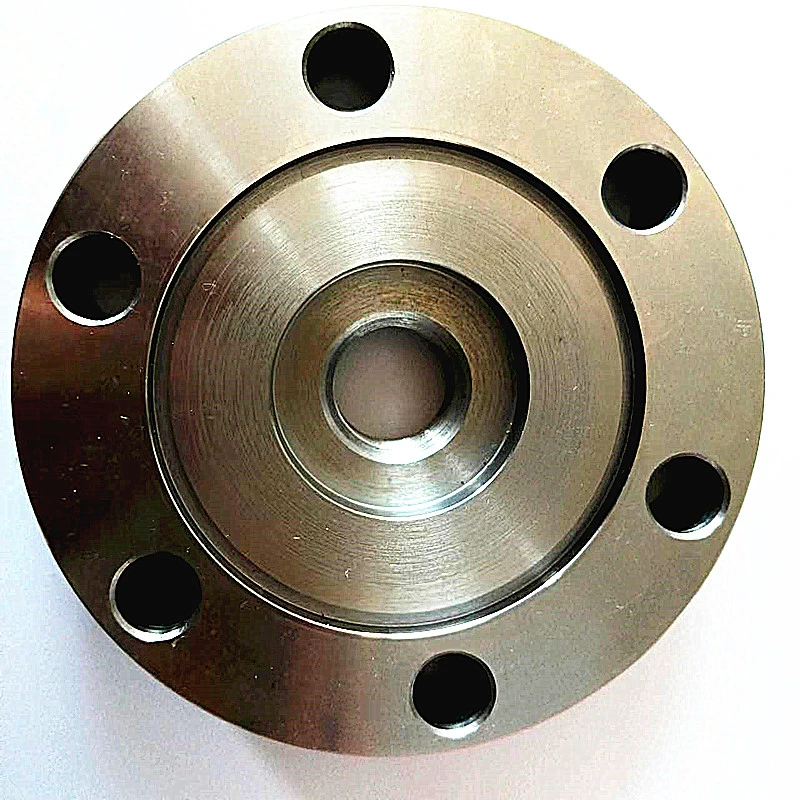

OEM Manufacturers Weld Neck Flange Titanium Stainless Steel 304 Weld Neck Flange Custom Carbon Steel Weld Neck Flange

Package Size 20.00cm * 20.00cm * 20.00cm Package Gross Weight 2.350kg 1.Q:Are you trading company or manufacturer?A: We

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | XBM-00771 |

| Standard | DIN, GB |

| Customized | Customized |

| Material | Stainless Steel ; Carbon Steel ; Alloy ; Aluminum |

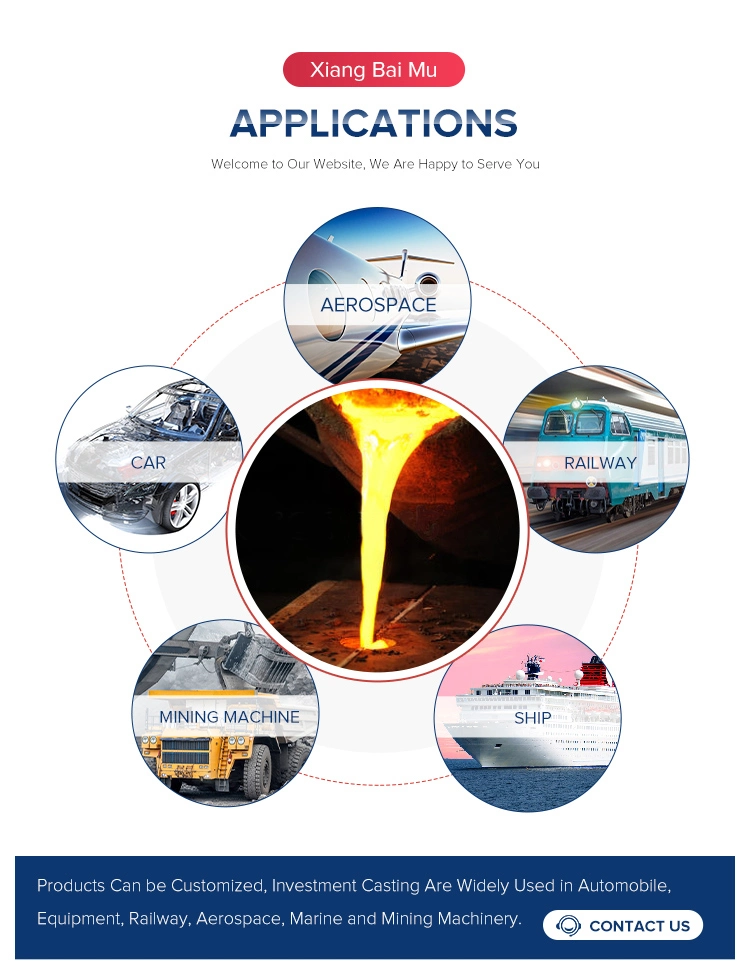

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Car Parts |

| Surface Treatment | Painting/Powder Coating/Sandblast/Electroplating |

| Part | OEM CNC Machining Parts |

| Materialproduct Description | Three-Axis / Five-Axis Processing, Milling Process |

| Weight Range | 0.1~80kg |

| Tolerance | 0.05mm |

| Service | OEM&ODM CNC Machining Part Per Custom |

| Name | CNC Machining Parts |

| Transport Package | Carton, Wooden Box or as Customer′s Requirements |

| Specification | standard |

| Trademark | XBM-007878 |

| Origin | Qingdao |

| HS Code | 8462999000 |

| Production Capacity | 10000 PCS Per Month |

Packaging & Delivery

Package Size 20.00cm * 20.00cm * 20.00cm Package Gross Weight 2.350kgProduct Description

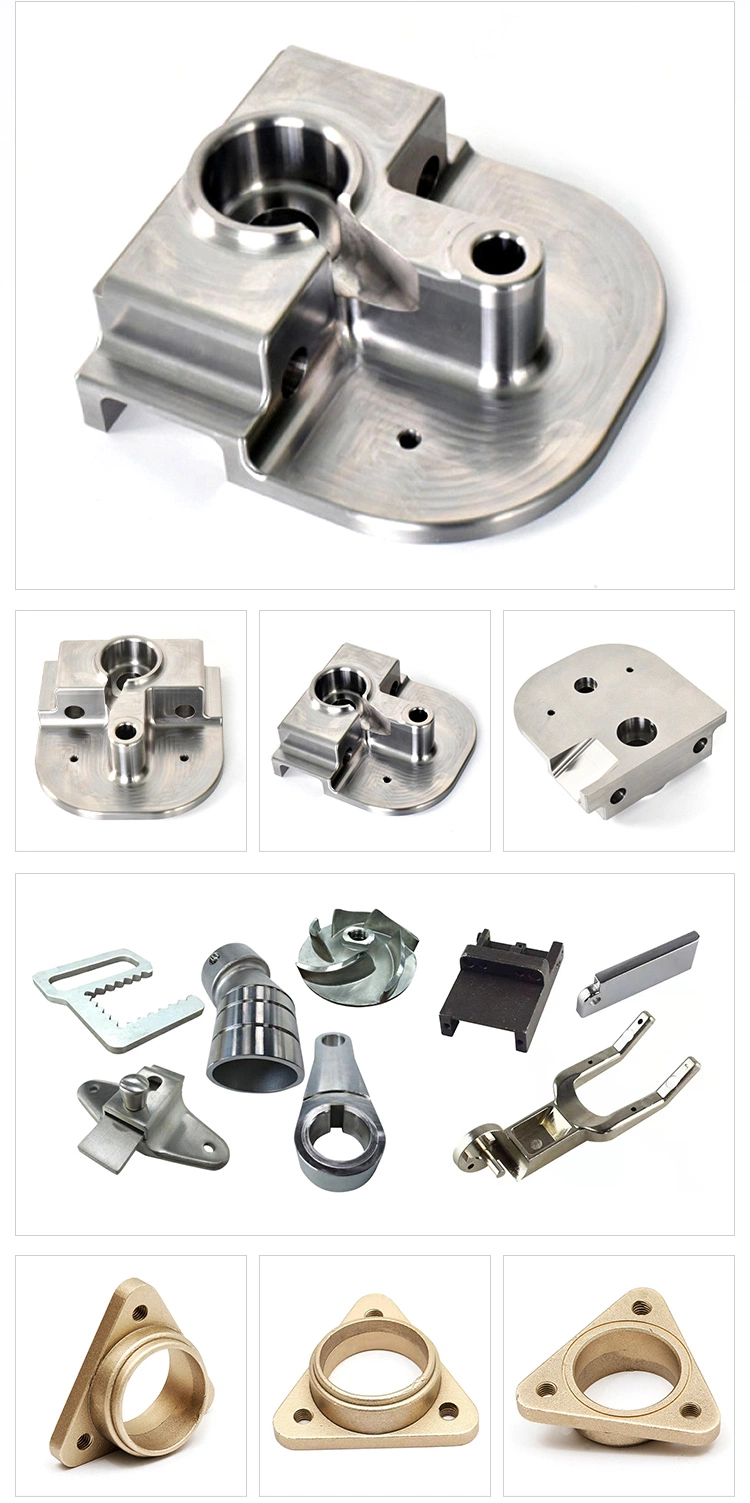

Product Name | cnc machining parts |

Material | Steel / aluminum alloy/Stainless steel/Copper/PlasticAny other material and dimension depends on customers' demand. |

Size | According to customers' requirement. |

Standard | DIN GB ISO JIS BA ANSI |

Processing | 1, Sign Drawing (General clients provide the drawing or samples)2, Precision Machining: Burring, Chamfering, Lathe, CNC milling and turning, Drilling, Grinding, Bending, Stamping, Tapping, etc3, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing,Rust preventive oil.4, Inspection and Packing |

Test Equipment | Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Application | Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, etc. |

Tolerance | +/-0.01mm-+/-0.05mm |

Q:Are you trading company or manufacturer?

A: We are factory with more then 15years experience2

Q: How long is your delivery time?

A: Generally it is 15-30days as we are Customized service we confirm with Customer whenplace order3

Q:Do you provide samples? ls it free or extra?

A: Yes we provide samples .for sample charge as per sample condition to decide free orcharged ,usually for not too much time used consumed machining process are free4

Q:What is your terms of payment?30% T/T in advance balance before shipment .Or as per discussion5

Q: Can we know the production process without visiting the factory?

A:We will offer detailed production schedule and send weekly reports with digitalpictures and videos which show the machining progress6

Q:Available for customized design drawings? A: YesDWG.DXF.DXW.IGES.STEP. PDF etc7

Q:Available for customized design drawings?

A: Yes ,we can sign the NDA before your send the drawing8

Q:How do you guarantee the quality?

A:(1) Checking the raw material after they reach our factory------Incoming quality control(IQC)(2) Checking the details before the production line operated(3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)(4) Checking the goods after they are finished---- Final quality control(FQC)(5) Checking the goods after they are finished-----Outgoing quality control(QC)(6)100% inspection and delivery before shipment.

Related Products

-

![Carbon Steel A105/A350 Lf2/Lf3 Alloy Steel A182 F5/ F9/F11/F12/F22/F91 Stainless Steel A182 F304/F321/F316 Wn/So/Pl/Bl/Sw/Thread Forged Flange]()

Carbon Steel A105/A350 Lf2/Lf3 Alloy Steel A182 F5/ F9/F11/F12/F22/F91 Stainless Steel A182 F304/F321/F316 Wn/So/Pl/Bl/Sw/Thread Forged Flange

-

![Hino700 Rear Axle Shaft Used for Super Dolphin Profia Fr4f Left Rear Drive Shaft]()

Hino700 Rear Axle Shaft Used for Super Dolphin Profia Fr4f Left Rear Drive Shaft

-

![Hino700 Rear Axle Shaft Used for Super Dolphin Profia Fr4f Left Rear Drive Shaft]()

Hino700 Rear Axle Shaft Used for Super Dolphin Profia Fr4f Left Rear Drive Shaft

-

![DN150 6 Inch Class150 Welding Neck Wn Flat Plate Threaded Blind Carbon DIN Pn16 As2129 BS4504 Sans 1123 ANSI Awwa 316L Stainless Steel Forged Flange]()

DN150 6 Inch Class150 Welding Neck Wn Flat Plate Threaded Blind Carbon DIN Pn16 As2129 BS4504 Sans 1123 ANSI Awwa 316L Stainless Steel Forged Flange